Plant Trolley System

Versatile, Quick & Easy to Use

Cost & Labour Saving

Versatile, quick and easy to use

- Purpose built for transporting plants!

- Easy to move - roll on, roll off and move around.

- Efficient loading & unloading - flexible shelf heights adjustable to 5cm intervals.

- Unload direct from trolley to displays, so staff can interact with customers.

- Easy to count and check off plants.

Cost savings for minimal investment

- Reduced handling - lower labour hours/costs.

- Protects valuable stock - less damaged stock.

- All from only 28 cents per day!

Labour saving – free your staff to do the important things!

- Reduced handling and packing/unpacking time.

- Quick to load and unload (users report up to 80% time savings).

Space saving

- Dispatching plants on multi shelf trolleys reduces the space required for dispatch area.

- Optimum use of truck space (emptied trolleys stack down to 15% of size).

- Reduction in use of other packing materials.

Care for your plants & your staff

- Less bending required – fewer injuries when correctly used.

- Safe method of transporting plants – reduction in breakages.

Low risk

- Fully maintained Trolleys and components.

- Swap system means you always have trolleys available.

- Full right of exchange with any other Plant Trolley.

The NZPPI Trolley System

- Each nursery, transporter or retailer hires the number of trolleys needed to run their business. They are responsible for ensuring no trolleys or components are lost.

- The receiver of loaded trolleys must always have an equal number of trolleys ready for exchange.

- The receiver of Trolleys checks that all trolleys are received complete, undamaged, clean and workable when exchanged.

- All damaged trolleys or components must be advised immediately to NZPPI and a replacement trolley or component will be organised.

How it Works

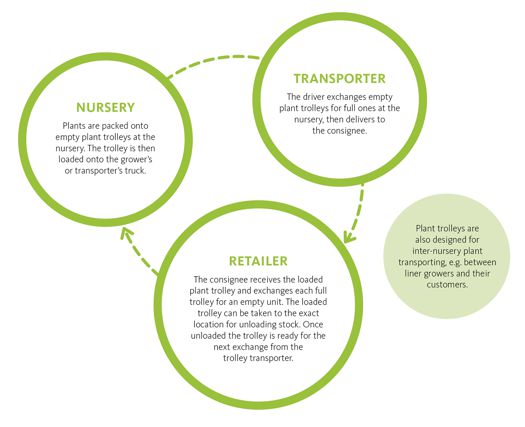

Nursery

Plants are packed onto empty plant trolleys at the nursery. The trolley is then loaded onto to the grower’s or transporter’s truck.

Transporter

The driver exchanges empty plant trolleys for full ones at the nursery then delivers to the consignee.

The Retailer

The consignee receives the loaded plant trolley and exchanges each full trolley for an empty unit. The loaded trolley can be pushed to the exact location for unloading stock. Once unloaded the trolley is ready for the next exchange from the Trolley transporter.

Plant Trolleys are also designed for inter-nursery plant transporting, i.e. between liner growers and their customers.

Trolley Specifications

Main frame: galvanised steel

Shelves: 7mm plywood with a phenolic resin surface

Carrying capcity: 75 kg per shelf, 300kg total

Dimensions: Height 2000mm, Depth 585mm, Width 1236mm

Typical loadings per shelf

- 20cm / 4.5 litre pots - 18 per shelf

- 17cm / 2.5 litre pots - 24 per shelf

- 14cm / 1.5 litre pots - 40 per shelf

- propagation / carry trays - 4 per shelf

Contact Us

Frances Palmer – Admin & Programme Manager

phone: (04) 918 3511

email: frances@nzppi.co.nz